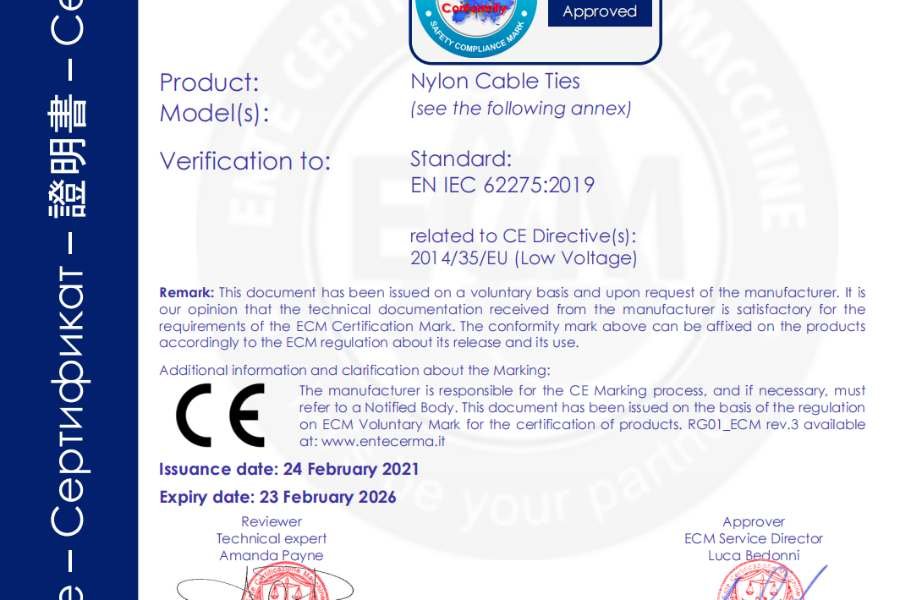

At HCT, we know you care about more than just products — you care about data behind every batch. Each cable tie is tested in our lab, from raw material to shipment, to meet global standards.

Our quality system is built on ISO9001, covering incoming, in-process, and outgoing checks. Test methods follow UL, IEC, and ASTM standards for globally recognized results.

Quality starts at the source. Every batch of nylon and stainless steel is tested for melting point, density, moisture, and flame resistance to ensure long-term stability.

Your project demands dependable strength. HCT uses tensile machines to simulate real installation conditions and verify breaking force across widths and temperatures.

For outdoor, coastal, and humid use, we run 48–500 hour salt spray tests to ensure corrosion resistance and reliable fastening in harsh conditions.

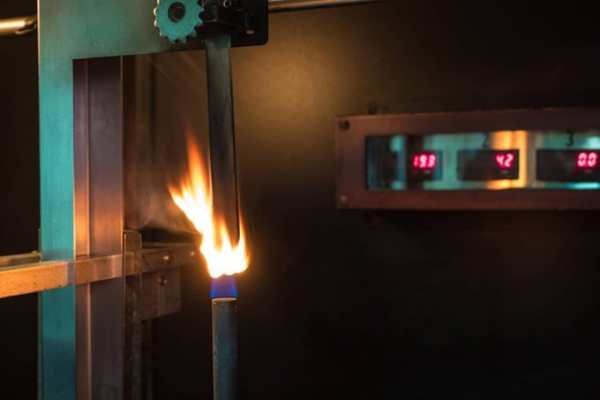

In electrical and energy sectors, fire safety is crucial. We perform vertical burning tests to confirm self-extinguishing time and ratings, meeting UL94V-2/V-0 standards.

Outdoor ties face sun, rain, and temperature shifts. HCT tests UV aging and thermal cycles to guarantee no fading or strength loss under outdoor exposure.

Precision defines quality. We use calipers and projectors to check tie width, tooth spacing, tail flatness, and color uniformity.

Each batch passes OQC checks before shipping. Every carton has a unique lot code linking back to material, process, and test records.

HCT provides tensile, salt spray, flame, and RoHS/REACH reports for every batch to support global audits and compliance.

Tell us your industry and standards, and we’ll customize a testing plan to match your application. HCT provides tensile, salt spray, flame, and RoHS/REACH reports for every batch to support global audits and compliance.

We will contact you within 1 working day. Please pay attention to the email with the suffix “@hcabletie.com”.