HCT supplies high-quality plastic cable ties, Nylon, PVC, Tefzel, PEEK, & More. Fast Supply & Private Label with exceptional tensile strength, low smoke, and temperature resistance, helping you grow your business with a wide range of cable ties.

OEM logo, packaging, and barcode available

Heat, UV, and chemical-resistant materials

Factory-direct pricing with fast production

HCT™ plastic cable ties are strong, lightweight, and ready for your toughest jobs. Made from premium materials such as nylon, PVC, Tefzel, and PEEK, our ties provide secure bundling for wires, hoses, and equipment across various industries.

Our plastic cable ties handle heat, UV, moisture, and chemicals with ease. Each batch is tested for strength and meets UL, RoHS, and REACH standards.

With over 12 years of experience and 15 production lines, we support global OEMs with custom sizes, private label packaging, and fast delivery. You get a one-stop solution—from design to shipping.

If you’re looking for reliable plastic cable ties for distribution, importing, or OEM use, HCT is your trusted partner.

Contact us today to get a free sample or fast quote.

HCT offers a full range of plastic cable ties made from different materials to fit every environment and industry. From high heat to cleanroom use, we’ve got you covered. Choose from nylon, PVC, PEEK, Tefzel, polypropylene, PC, and Halar. Each type comes in multiple lengths, strengths, and colors.

Whether you’re looking for UV-resistant, releasable, fire-rated, or chemical-proof cable ties, Peflon provides the best solution with fast OEM service.

Explore our categories below and get in touch for free samples or pricing.

HCT offers a full line of plastic cable ties designed for specific functions and extreme environments. Whether you need UV-resistant, heat-proof, or reusable cable ties, we have a solution that fits. Choose from metal-reinforced, screw-mount, plenum-rated, or radiation-resistant options to meet the most demanding industrial needs.

Browse by function to find the best fit for your project.

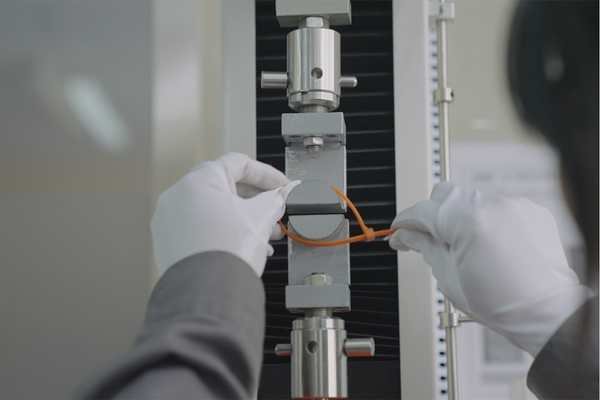

HCT’s core competency is rooted in our relentless pursuit of precision mold development and stable process control.We operate our own R&D center for mold development, enabling us to design and manufacture high-precision molds. Thus ensuring that the locking teeth on every HCT cable tie are perfectly formed for smooth, secure locking, fundamentally preventing slippage and failures.Our production floor utilizes fully enclosed, automated injection molding cells integrated with real-time vision inspection systems.

MOQ from 10,000 pcs, support startup and niche orders

Private label with logo, barcode, and color match

Delivery in 7–15 days with flexible packing options

Full compliance: UL 94V-2, RoHS, REACH, halogen-free

Lab reports and MSDS provided with each shipment

Tensile strength & aging tested batch-by-batch

40+ years of cable tie production experience

15 production lines, monthly capacity over 30 million pcs

Export to 50+ countries with 98.3% on-time delivery rate

Yes, HCT supports OEM orders with custom lengths, colors, and labeling.

We recommend UV-resistant nylon or Tefzel cable ties for long-term outdoor use.

bsolutely. Our ties meet UL, RoHS, and REACH standards across most materials.

Yes. Samples are available upon request for testing and approval.

Standard lead time is 7–15 days, depending on quantity and customization needs.

Contact HCT today for the latest cable tie quotations and custom solutions. Our team responds fast to keep your procurement smooth and efficient. Click below to start your partnership journey.

We will contact you within 1 working day. Please pay attention to the email with the suffix “@hcabletie.com”.