stainless steel zip tie is the strongest type. In industrial fastening, not all cable ties are built the same. If you’re an importer, distributor or OEM manufacturer, choosing the right strength level means fewer failures, smoother logistics, and happier clients.

Why Strength Matters in Global Supply

When a zip tie breaks in use, it’s not just a small loss — it’s a chain reaction. Returns, downtime, or rework costs hit importers, distributors, and OEMs alike.

One Japanese OEM brand, supplying wiring harnesses for construction machinery, once faced a 1.5 % field failure rate using standard nylon ties. After switching to 250 lb-rated heavy-duty ties from HCT, their failure rate dropped below 0.3 %, saving more than ¥4.2 million (≈ USD 27 000) in service claims within a year.

That’s the difference real tensile strength makes.

Understanding Tensile Strength

Loop tensile strength measures how much force a tie withstands before breaking when locked in a loop. It’s the practical metric for reliability in use — not just a material number.

| Type | Typical Material | Tensile Strength | Common Use |

|---|---|---|---|

| Standard Nylon Tie | PA66 | 18 – 50 lbs (8 – 23 kg) | Light wiring, indoor use |

| Heavy-Duty Nylon Tie | Reinforced PA66 | 120 – 250 lbs (54 – 113 kg) | Industrial panels, outdoor, solar |

| Stainless Steel Tie | 304 / 316 SS | 300 – 900 lbs (136 – 408 kg) | Marine, chemical, high-temp |

Choosing the Right Type for Your Market

Standard Nylon

- Economical, easy to source, perfect for everyday cable bundling.

- Visit Nylon Cable Ties for available specs.

Heavy-Duty Nylon

- Reinforced PA66 material with UV and heat stabilization.

- Ideal for OEM or export clients needing high performance but controlled cost.

- Heavy-Duty Zip Ties →

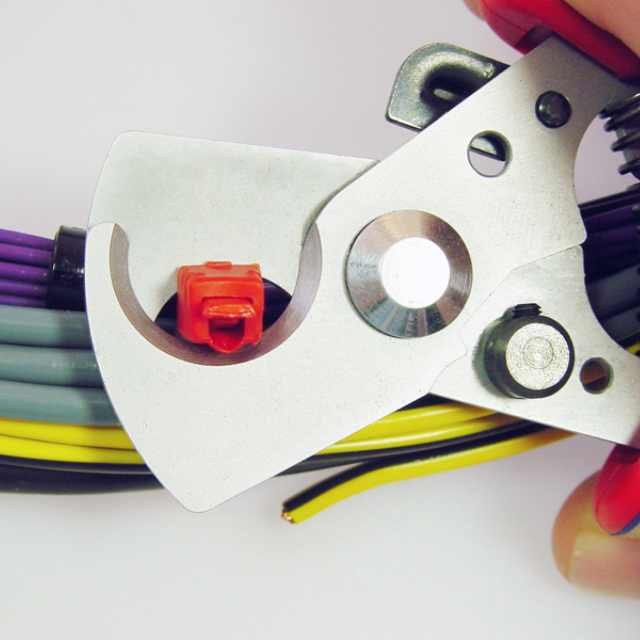

Stainless Steel

- For extreme environments — shipbuilding, tunnels, chemical plants.

- 304 / 316 grades resist corrosion and maintain strength up to +500 °C.

- Stainless Steel Cable Ties →

What Importers and OEMs Should Check

- Material certificates – confirm PA66 or 316 SS grade.

- Loop tensile test reports – request actual data from each batch.

- Compliance – verify UL 62275 Type 21 or UL94 V-2 for nylon.

- Packaging details – tensile strength (lbs/kg), batch ID, origin.

- Transport storage – avoid moisture and direct UV during long shipping.

A Japanese importer recently noted:

“Consistency in tensile results was more important than absolute max strength. HCT’s reports matched within ±5 % variance across shipments — that gave us confidence.”

Cost vs Performance Balance

| Type | Approx. Unit Cost (per 1000 pcs) | Best for |

|---|---|---|

| Standard Nylon | Low | Mass retail / low-risk use |

| Heavy-Duty Nylon | Medium | Industrial OEM projects |

| Stainless Steel | High | Harsh environments / premium exports |

Bulk buyers (≥ 250 lb rated) often achieve 5–10 % better pricing through scheduled production runs — ideal for importers maintaining steady volume.

FAQ

Q: Are black ties always stronger?

Not necessarily — black usually means UV-resistant, not higher tensile rating.

Q: Can multiple ties be combined for more strength?

Yes, roughly additive if evenly loaded, but not exact. Always check rated load.

Q: What’s best for marine or chemical exposure?

Use 316 stainless steel with proven salt-spray test data.

Q: How to check real strength before import?

Ask for manufacturer’s loop tensile test report — HCT provides this on request.

Ready to Strengthen Your Line?

Explore our full range of

Nylon Cable Ties,

Heavy-Duty Zip Ties, and

Stainless Steel Cable Ties.

Contact our export team to request samples, MOQ details and tensile test reports.

Contact Us →