Cable ties might look simple—but choosing the right size makes all the difference.

Whether you’re importing, wholesaling, or producing under your OEM brand, the right dimensions can directly impact your costs, logistics, and product reliability.

Let’s break it down step by step.

Why Cable Tie Sizes Matter

Each cable tie dimension serves a unique purpose. A 2.5 mm width works perfectly for small wire bundles, while a 12 mm heavy-duty tie can hold loads exceeding 100 kg.

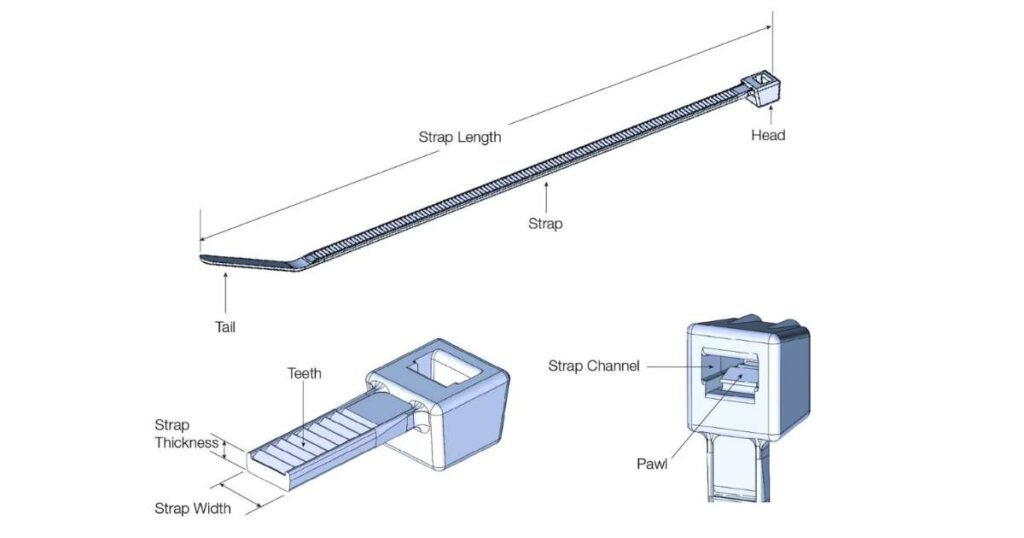

Here are the four key measurements you should know:

- Length – determines how large a bundle you can secure.

- Width – affects tensile strength and material cost.

- Bundle diameter – defines how much material the tie can wrap.

- Tensile strength – measured in lbs or kg; this is how much weight it can hold before breaking.

Choosing the correct combination isn’t just about engineering—it’s about balancing performance, efficiency, and profitability.

So, how do you decide what fits your market best?

Common Cable Tie Sizes by Application

Small / Light-Duty Applications (Home & Office)

- Typical range: 100 mm–150 mm long × 2.5 mm–3.6 mm wide

- Tensile strength: around 8–18 lbs

- Use cases: desktop wiring, small appliances, retail packaging

- Wholesale tip: nylon 66, natural color, 1 000 pcs per bag for cost efficiency

Medium / Industrial Applications (Electrical & Construction)

- Typical range: 200 mm–400 mm long × 4.8 mm–7.6 mm wide

- Tensile strength: around 40–80 lbs

- Use cases: electrical panels, cable trays, machine assemblies

- Wholesale tip: bundle two popular specs (4.8 × 200 mm and 7.6 × 300 mm) to cover 80 % of customer needs

Large / Heavy-Duty Applications (Outdoor & Structural)

- Typical range: 450 mm–1200 mm long × 9 mm–12 mm wide

- Tensile strength: 100–175 lbs

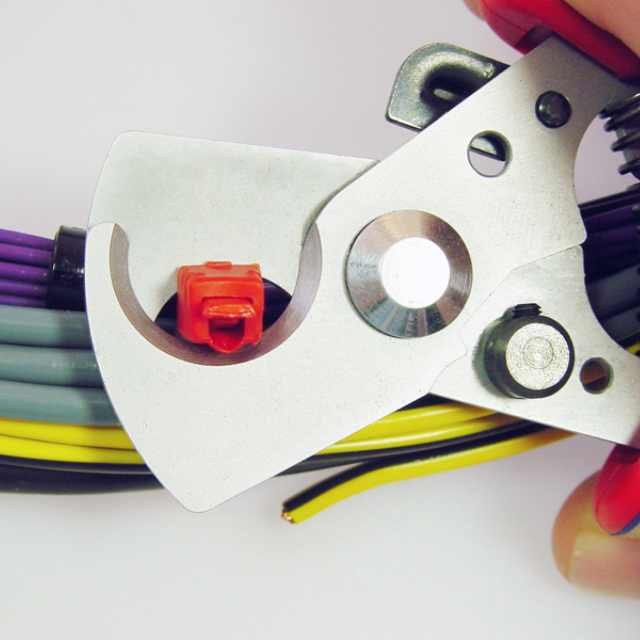

- Use cases: telecom towers, pipelines, automotive harnesses

- Wholesale tip: use UV-resistant or stainless-steel ties for longer outdoor lifespan

| Type | Length (mm) | Length (inch) | Width (mm) | Width (inch) | Tensile Strength (N) | Tensile Strength (kgf) | Tensile Strength (lbs) | Typical Application |

| Small | 60 | 2.36 | 2.5 | 0.10 | 80 | 8 | 18 | Electronic wires, small bundles |

| Small | 80 | 3.15 | 2.5 | 0.10 | 80 | 8 | 18 | Light-duty wiring |

| Small | 100 | 3.94 | 2.5 | 0.10 | 80 | 8 | 18 | Electronic components |

| Small | 120 | 4.72 | 2.5 | 0.10 | 80 | 8 | 18 | Small appliances |

| Small | 120 | 4.72 | 3.6 | 0.14 | 150 | 15 | 34 | Appliance internal wiring |

| Small | 140 | 5.51 | 3.6 | 0.14 | 150 | 15 | 34 | Control panel wiring |

| Small | 150 | 5.91 | 3.6 | 0.14 | 150 | 15 | 34 | Computer wires |

| Medium | 160 | 6.30 | 3.6 | 0.14 | 180 | 18 | 40 | Electrical cabinets |

| Medium | 180 | 7.09 | 3.6 | 0.14 | 180 | 18 | 40 | General wiring |

| Medium | 200 | 7.87 | 3.6 | 0.14 | 180 | 18 | 40 | Electrical installations |

| Medium | 200 | 7.87 | 4.8 | 0.19 | 220 | 22 | 49 | Industrial cables |

| Medium | 250 | 9.84 | 3.6 | 0.14 | 180 | 18 | 40 | Automotive wiring |

| Medium | 250 | 9.84 | 4.8 | 0.19 | 220 | 22 | 49 | Machinery wiring |

| Medium | 280 | 11.02 | 4.8 | 0.19 | 220 | 22 | 49 | Control boxes |

| Medium | 300 | 11.81 | 4.8 | 0.19 | 220 | 22 | 49 | General electromechanical |

| Large | 300 | 11.81 | 7.6 | 0.30 | 540 | 55 | 121 | Communication cabinets |

| Large | 350 | 13.78 | 7.6 | 0.30 | 540 | 55 | 121 | Engineering use |

| Large | 370 | 14.57 | 7.6 | 0.30 | 540 | 55 | 121 | Outdoor cable |

| Large | 400 | 15.75 | 7.6 | 0.30 | 540 | 55 | 121 | Cable trays |

| Large | 450 | 17.72 | 7.6 | 0.30 | 540 | 55 | 121 | Pipe fixing |

| Heavy-Duty | 520 | 20.47 | 9 | 0.35 | 780 | 80 | 175 | Pipe & cable |

| Heavy-Duty | 600 | 23.62 | 9 | 0.35 | 780 | 80 | 175 | Industrial equipment |

| Heavy-Duty | 760 | 29.92 | 9 | 0.35 | 780 | 80 | 175 | Construction site |

| Heavy-Duty | 900 | 35.43 | 12 | 0.47 | 1140 | 116 | 256 | Heavy machinery |

| Heavy-Duty | 1000 | 39.37 | 12 | 0.47 | 1140 | 116 | 256 | Heavy load cable |

| Heavy-Duty | 1200 | 47.24 | 12 | 0.47 | 1140 | 116 | 256 | Replace metal ties |

Five Sizing Factors Wholesalers & OEMs Should Consider

1. Cost vs Strength vs Packaging Efficiency

Wider or longer ties increase strength but raise material cost.

Many OEM brands save 10–15 % in material cost simply by switching to a shorter or narrower tie while maintaining the same performance.

2. Customization & Branding Options

Color, logo printing, and packaging style can elevate your product line.

Typical MOQ: 10 000 pcs per size; lead time: 15–25 days for custom runs.

3. Packaging & Logistics Optimization

- Bulk packs: 1 000 pcs / bag × 10 bags / carton

- Retail packs: 100 pcs / bag for e-commerce

- Mix boxes: combine small + medium + large to reduce SKUs and speed up turnover

4. Quality Standards & Certifications

Ensure your supplier complies with UL 62275, RoHS, and REACH—especially for export to Europe and North America.

5. Market Trends & Differentiation

Reusable ties → Eco-friendly markets (EU / Canada)

Metal-detectable ties → Food & pharma industries

UV-resistant ties → Outdoor & telecom projects

Case Studies: How Size Optimization Drives Profit

Case 1: OEM Manufacturer (Europe)

Switched from 7.6 mm × 400 mm to 6 mm × 300 mm.

→ Saved 12 % on material costs, roughly €18 000 per year, without sacrificing strength.

Case 2: Importer (Southeast Asia)

Consolidated two SKUs (4.8 × 200 mm and 8 × 150 mm) into combo packaging.

→ Reduced SKUs by 30 %, lowered warehouse cost by 8 %, and improved stock turnover by 14 days.

Case 3: Wholesaler (USA)

Added UV-black outdoor grade to existing line.

→ Average selling price up 15 %, entering new B2B segments in construction and utilities.

The data is clear—smart sizing equals better margins.

FAQs – Cable Tie Sizes for Trade Buyers

Q1: How does tensile strength relate to width?

Each extra 1 mm of width increases tensile strength by roughly 15–20 %.

Q2: What’s best for outdoor installation?

Use UV-resistant nylon 66 or stainless steel ties.

Q3: Can we print our OEM logo on ties?

Yes—ideal logo area is about 2 mm high × 15 mm long; lighter colors print best.

Q4: How should we plan inventory by size?

Keep at least three core sizes (Small / Medium / Large) and track monthly sales volume to forecast restocks.

Q5: What’s the minimum order quantity (MOQ)?

Standard stock: 1 000 pcs / size. Custom orders: 10 000 pcs / size minimum

Review Your Cable Tie Strategy Today

Start by testing your current product mix.

Which sizes move fastest? Which ones stay in inventory too long?

Re-evaluate your range, talk with your supplier, and test smaller sample runs to find your best-selling specs.

Contact our team → View Cable Tie Products

Or learn more technical insights on Wikipedia – Cable Tie.