Stainless steel cable ties give your customers a secure way to bundle, fasten, and protect cables in harsh environments. As a distributor, you need a guide that not only explains how they work but also helps you answer common questions from installers and OEM buyers. This page walks through how stainless steel cable ties are used, how to tighten them correctly, and what specifications matter most in real industrial applications.

What Stainless Steel Cable Ties Are (and When They’re the Right Choice)

Stainless steel cable ties are made from thin metal bands with a locking mechanism that secures the tie once tension is applied. They perform well where nylon ties fail—especially under high heat, UV exposure, corrosion, or constant vibration.

Typical industries that rely on stainless steel ties include:

- Solar energy (cable routing under strong heat and sunlight)

- Shipbuilding and marine (saltwater-resistant installations)

- HVAC and ventilation systems

- Petrochemical and industrial plants

When a customer needs durability above 120 °C, exposure to chemicals, or long-term outdoor use, stainless steel cable ties are usually the correct recommendation.

Types of Stainless Steel Cable Ties Your Customers Will Ask About

Ball-Lock Stainless Steel Cable Ties

These are the most common design. A stainless-steel ball inside the head grips the band as soon as tension is applied.

Key points distributors should know:

- Fast installation for field technicians

- Strong resistance to vibration

- Best-selling sizes: 150 mm, 200 mm, 360 mm, 520 mm

Ladder-Type Stainless Steel Cable Ties

Instead of a ball-lock head, ladder-type ties use a series of locking positions.

Useful when:

- Installers need adjustable tension

- Bundles are irregular

- A lower-cost stainless option is preferred

Coated Stainless Steel Cable Ties

These ties come with PVC or polyester coating.

Why coatings matter:

- Prevents scratches on painted surfaces

- Offers electrical insulation

- Preferred in telecom, railway, and marine applications

Material Grades: 304 vs 316

- 304: General industry, warehouse stock

- 316: Marine, chemical, chloride-rich environments

Most distributors keep a 70% (304) + 30% (316) mix to meet demand across industries.

Key Specifications Distributors Should Know

Your customers often compare cable ties based on a few critical specs:

- Tensile strength: Typically 80–250 kg, depending on width

- Operating temperature: –80 °C to +540 °C

- Coating thickness: 0.25–0.5 mm for coated versions

- Common widths: 4.6 mm, 7.9 mm, 12 mm

Keeping a balanced size range helps you serve both retail orders and industrial buyers.

How to Use Stainless Steel Cable Ties (Step-by-Step)

Below is the standard installation procedure your customers follow:

1. Loop the Tie Around the Object

Keep the smooth side facing inward for better tension distribution. Leave 20–30 mm of extra tail for tightening.

2. Insert the Tail Into the Locking Mechanism

Push the tail through until you feel or hear engagement. Make sure the band is straight before you continue.

3. Apply Tension

You can tighten the tie by hand or by using a tensioning tool (recommended for loads heavier than 50 kg).

4. Cut the Excess Tail

A flat cut prevents sharp edges—especially important in HVAC, solar, and marine installations.

How to Tighten Stainless Steel Cable Ties Correctly

Hand Tightening

Hand tightening works for small bundles, light-duty wiring, or quick temporary fixes. It is not recommended for environments with strong vibration.

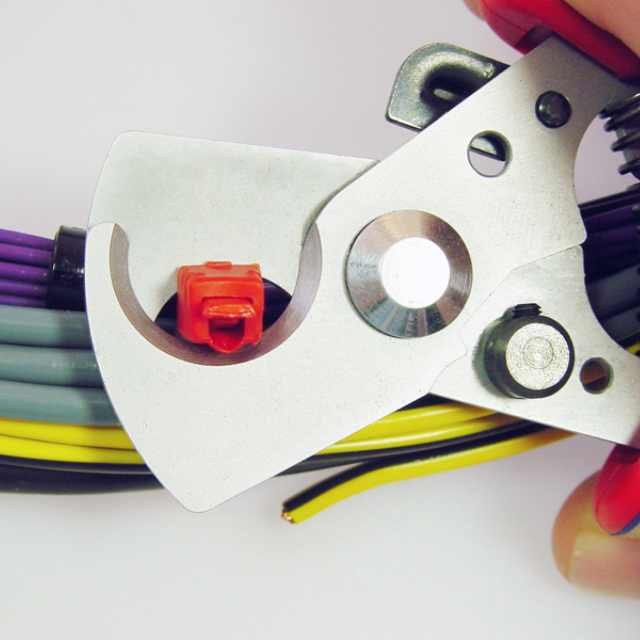

Using a Tensioning Tool

Most industrial installers use a tensioning gun. It helps:

- Apply consistent force

- Prevent over-tightening

- Automatically cut the tail flush

This is a great add-on product for distributors, as many customers purchase tools and stainless ties together.

Types of tools you may stock:

- Manual tensioning gun

- Heavy-duty ratchet tension tool

- Automatic cut-off gun

Common Installation Mistakes to Avoid

Installers often run into performance issues because of these mistakes:

- Overtightening, which deforms the band

- Under-tensioning, causing slippage

- Using 304 instead of 316 in corrosive environments

- Using uncoated ties where insulation is required

- Cutting the tail with non-flush tools, leaving sharp edges

Sharing these points with customers helps reduce warranty claims and installation errors.

Industry Applications (With Practical Examples)

- Solar farms: Securing cables on metal structures exposed to heat and UV

- Shipbuilding: Withstanding saltwater and oil spray

- Petrochemical plants: Resistant to high heat and chemical exposure

- HVAC systems: Stabilizing ducts and insulation under vibration

Each industry has preferred sizes and coating choices, giving distributors clues for smarter stocking decisions.

Quick Comparison Tables

Ball-Lock vs Ladder-Type vs Coated

| Type | Strength | Flexibility | Best For |

|---|---|---|---|

| Ball-Lock | Highest | Medium | Heavy-duty, outdoor, vibration zones |

| Ladder-Type | Medium | High | Irregular bundles, adjustable tension |

| Coated | Medium–High | High | Telecom, marine, painted surfaces |

304 vs 316 Stainless Steel

| Grade | Corrosion Resistance | Typical Price | Industries |

|---|---|---|---|

| 304 | Good | Lower | General industrial use |

| 316 | Excellent | Higher | Marine, chemical, chloride exposure |

FAQs

Are stainless steel cable ties reusable?

No. Once locked, they cannot be reopened without cutting the band.

What tools do I need to tighten stainless steel cable ties?

A manual or automatic tensioning gun provides the best results for industrial use.

What temperature can they withstand?

Most stainless steel ties operate from –80 °C to +540 °C.

Can they be used outdoors long-term?

Yes. Stainless steel ties resist UV, weather, and corrosion.

When should customers choose coated stainless steel ties?

When surface protection or electrical insulation is required.

Related Resources

If you’re a distributor stocking stainless steel cable ties, we can support you with full-size ranges, private-label packaging, and fast export shipments.

Request pricing or samples today.