Yes, you can undo a standard zip tie without cutting it. While most people view standard cable ties as single-use fasteners, the mechanism inside allows for release if you know where to look.

However, just because you can reuse a standard tie doesn’t mean you always should. For importers and distributors serving industrial clients, understanding the mechanics behind this—and the physical limitations of reused nylon—is key to recommending the right product.

This guide explains the technical method to unlock a zip tie, the hidden risks of reusing them, and when to upgrade to Releasable Cable Ties.

Understanding the Mechanism: The Pawl and the Rack

To unlock a zip tie, you first need to understand how it locks. A standard cable tie consists of two main active parts:

- The Rack (Teeth): Serrated teeth running along one side of the strap.

- The Pawl (Locking Wedge): A small, flexible lever inside the head of the tie.

When you insert the tail into the head, the pawl rides over the sloped side of the teeth (making that familiar "zip" sound). When you pull back, the pawl digs into the flat side of the teeth, locking the strap in place. This is a ratchet mechanism.

Most high-quality ties are made from Nylon 66. This material is chosen for its balance of strength and flexibility. The pawl needs to be flexible enough to bend as you tighten the tie, but rigid enough to spring back and lock.

Step-by-Step: How to Undo a Standard Zip Tie

If you are in a pinch or testing a prototype, you can manipulate the pawl to release the strap.

What you need:

- A thin, rigid point (a safety pin, a sewing needle, or a precision jeweler’s screwdriver).

- Good lighting.

The Process:

- Locate the Mechanism: Look closely at the head of the zip tie. You will see the strap entering the box-shaped head. The locking pawl is the small plastic lever inside that touches the teeth of the strap.

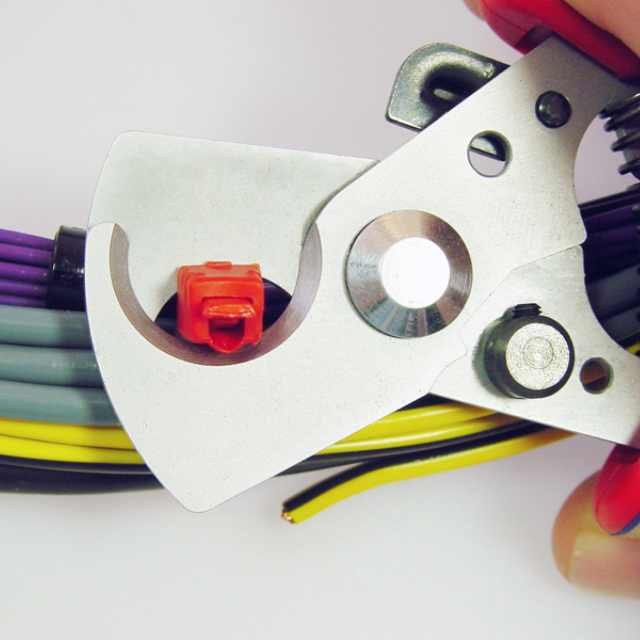

- Insert the Tool: Carefully slide your pin or screwdriver between the pawl and the teeth of the strap.

- Disengage the Lock: Gently lever the handle of your tool to pry the pawl away from the teeth. You are trying to create a tiny gap so the teeth no longer touch the locking wedge.

- Pull the Tail: While holding the pawl open with your tool, use your other hand to pull the strap backwards out of the head. It should slide out smoothly.

Note: Do not force the strap. If it is stuck, you likely haven’t lifted the pawl high enough. Forcing it will damage the teeth.

The Hidden Risks: Why Reusing Standard Ties is Dangerous

For DIY projects, reusing a zip tie is fine. But in B2B sectors—like automotive manufacturing, electrical contracting, or heavy machinery—we advise against reusing standard ties for permanent installation.

Here is the technical reason: Plastic Deformation.

When a Nylon 66 pawl is under load, it experiences stress. Over time, or after being pried open with a metal pin, the plastic suffers from fatigue.

- Tensile Strength Loss: A reused standard tie can lose 10% to 20% of its original loop tensile strength. The pawl may not snap back to its original position fully, leading to a weaker grip.

- Damaged Teeth: The metal tool used to unlock the tie often scratches or deforms the nylon teeth on the rack. This creates weak points where the tie could slip under vibration.

If your customers need to secure heavy cables or ensure safety compliance, a reused tie is a liability.

The Professional Alternative: Releasable Cable Ties

If your application requires frequent changes—such as temporary wiring, trade show setups, or prototype harnesses—standard ties are the wrong tool. This is where Releasable Cable Ties provide value.

These ties feature an extended finger latch or button built directly into the head. You simply press the lever to disengage the pawl—no tools required.

Standard vs. Releasable: A Quick Comparison

| Feature | Standard Nylon Tie | Releasable Cable Tie |

|---|---|---|

| Mechanism | Internal locking pawl (Hidden) | Extended finger latch (Accessible) |

| Release Method | Requires tool (Pin/Screwdriver) | Manual trigger (Finger press) |

| Reuse Cycle | Not recommended for load bearing | Engineered for multiple cycles |

| Tensile Strength | High (e.g., 50lbs for standard width) | Moderate to High (varies by design) |

| Best Use | Permanent installation | Maintenance, prototyping, temporary events |

For distributors, stocking releasable ties offers a solution for clients who waste labor hours cutting and replacing ties during maintenance.

Frequently Asked Questions

1. Can I recycle cut zip ties?

Yes, most cable ties are made from Nylon 66 (Polyamide), which is a thermoplastic. However, you should check with your local recycling facility, as small plastic parts are sometimes filtered out of standard recycling streams.

2. Do metal barb cable ties work the same way?

No. Some high-strength ties use a stainless steel barb (a metal tooth) instead of a plastic pawl. These bite into the strap very aggressively. While technically possible to pick open, it is much more difficult and usually destroys the strap surface.

Summary

Unlocking a zip tie is a useful skill for quick fixes, but it is not a scalable industrial solution. The risk of reduced tensile strength makes reused ties unsuitable for critical manufacturing or shipping needs.

For reliable, repeatable performance, choose the right tool for the job.

Need a sample of our Releasable Series?

We offer a full range of releasable ties for distributors and OEMs. Contact our export team today to request your sample kit or download the technical specification sheet.