For a distributor, a cable tie is often seen as a “C-class” commodity. It is a low-cost item that usually flies under the radar. But if you have ever had a customer complain that a batch of ties snapped during installation in freezing weather, you know the hidden cost of this product.

A single broken tie can slow down an assembly line or force an electrician to redo their work. For you, that means returns, credit notes, and damaged trust.

At Hct Cable Tie, we believe the difference between a reliable product and a liability lies in the material science and manufacturing precision. This guide covers what professional buyers need to know about Nylon 6/6, how to prevent the dreaded “brittleness” issue, and how to spot quality defects before they reach your warehouse.

Why Nylon 6/6 is the Industry Standard

You will see many types of plastic used in fasteners, but Polyamide 6.6 (PA66), commonly known as Nylon 6/6, remains the global standard for general-purpose cable ties.

Why do we use it? It offers the best balance for general industrial use. It is strong enough to hold heavy bundles but flexible enough to lock tightly without snapping.

Material Comparison

If you are supplying specific industries (like chemical plants), you might need alternatives. Here is how standard PA66 compares to other common materials:

| Material | Continuous Temp Range | Chemical Resistance | Best Use Case |

|---|---|---|---|

| Nylon 6/6 (PA66) | -40°C to +85°C | Good (Oils, Greases) | General indoor, wire bundling, construction. |

| Nylon 6/12 | -40°C to +105°C | Excellent (Chemicals) | Solar farms, chemical processing. |

| Polypropylene (PP) | -40°C to +115°C | High (Acids) | Chemical environments where tensile strength is less critical. |

Note: Standard Nylon 6/6 is not UV resistant by default. For outdoor use, you must specify UV Stabilized (Black) ties, which contain Carbon Black to block UV radiation.

[Image of chemical structure of Nylon 66]

Understanding Tensile Strength and UL Ratings

When you read a spec sheet, the most important number is Loop Tensile Strength (LTS). This measures how much force the tie can withstand while locked before it breaks or the pawl (the locking tooth) slips.

We test this by forming a loop and pulling it apart with a calibrated machine until failure. To meet international standards (like UL 62275), our ties must meet these minimum ratings:

- Miniature (2.5mm width): 18 lbs (8 kg)

- Intermediate (3.6mm width): 40 lbs (18 kg)

- Standard (4.8mm width): 50 lbs (22 kg)

- Heavy Duty (7.6mm width): 120 lbs (55 kg)

- Extra Heavy Duty (9.0mm – 12.7mm): 175 lbs – 250 lbs (79 kg – 114 kg)

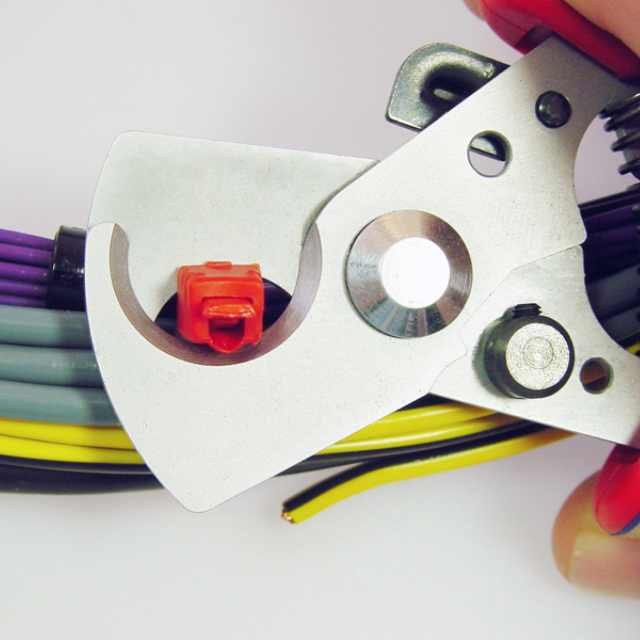

A Simple Quality Check

You don’t always need a lab to test quality. Try the “Bend Test”:

- Take a standard 4.8mm cable tie.

- Bend the tail completely back until it touches the head.

- If it snaps immediately, the nylon is too dry or made of poor recycled material. A quality tie should bend without breaking.

The Hidden Killer: Moisture and Brittleness

This is the number one source of complaints in the cable tie industry: “Why are my ties snapping?”

The answer is usually water—or the lack of it.

The 2.5% Water Rule

Nylon 6/6 is hygroscopic. This means it absorbs and releases moisture from the air.

- Fresh from the mold: The nylon is bone-dry and naturally brittle.

- Water Injection: We add about 2.5% moisture content to the bag before sealing. This makes the nylon flexible and tough.

If a bag is left open, or if the ties are stored in a very hot, dry warehouse, the water evaporates. The ties return to their “dry state” and become brittle.

Storage Tips for Distributors

To protect your inventory and your reputation, share these rules with your warehouse team:

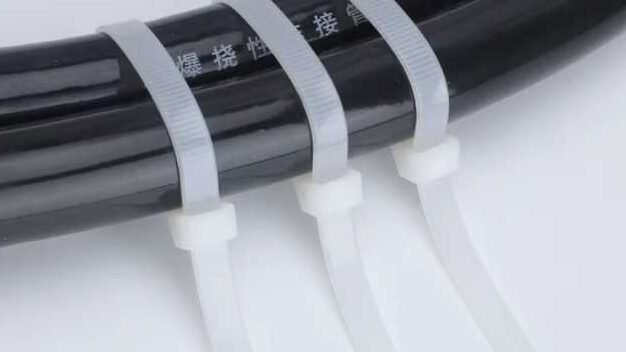

- Do not open the bag until ready to use. The plastic bag is the barrier keeping the moisture in.

- Store away from direct heat. Do not place pallets next to radiators or under direct sunlight (even through windows).

- Ideal Conditions: 23°C (73°F) with 50% relative humidity.

If you have old stock that has dried out, you can sometimes “save” them by adding a few drops of water to the bag and resealing it for a week, though fresh stock is always safer.

Quality Control: Virgin vs. Reground Material

In the B2B market, price pressure is high. Some manufacturers cut costs by mixing Reground Material (scrap plastic or “runners” from previous production) with Virgin Material.

While a small percentage (e.g., 5%) of regrind is acceptable in some low-stress plastic products, it is dangerous for cable ties.

The Risk of Regrind

Every time Nylon is melted and cooled, its molecular chains get shorter. This degrades the material. A cable tie made with high levels of regrind will:

- Have 20-30% lower tensile strength.

- Snap easily in cold temperatures.

- Yellow faster over time.

How to Spot Regrind

Inspect your samples closely. Virgin Nylon 6/6 should be:

- Clear/Translucent (for natural ties).

- Free of dark specks or “smoke” marks.

- Consistent in color.

If the “natural” tie looks murky, grey, or has a brownish tint, it likely contains high levels of reground material. At H Cable Tie, we use Virgin PA66 from reputable suppliers to ensure consistent performance.

OEM & Packaging: Adding Value to Your Brand

For importers and distributors, the product is only half the battle. The other half is how it looks on the shelf. We offer flexible OEM solutions to fit your sales channel.

Custom Packaging Options

- Standard Polybag: The most cost-effective choice. We print your logo and barcode directly on the bag or apply a sticker. Ideal for bulk sales to contractors.

- Euro-Hole Header Card: Essential for retail environments. The reinforced header allows the bag to hang on pegboards without tearing. This commands a higher retail price point.

- Canisters/Tubs: Popular for DIY stores. A tub of 500 or 1,000 assorted ties offers great value to the end-user and acts as a permanent storage solution.

Private Labeling

We can create a private label mold for you. This involves engraving your brand name directly onto the head of the cable tie.

- Pros: Ultimate brand protection; competitors cannot copy your product easily.

- Cons: Requires a longer initial lead time for mold creation and slightly higher MOQs.

Sourcing and Logistics FAQ

Q: What is the HS Code for Nylon Cable Ties?

A: The standard Harmonized System (HS) code is 3926.90. Always verify with your local customs broker as codes can vary slightly by country.

Q: How many cartons fit in a container?

A: This depends on the mix of sizes (miniature ties take up less space than heavy-duty ones).

- 20ft Container: Approx. 800 – 1,000 cartons.

- 40ft HQ: Approx. 2,000 – 2,200 cartons.

- Tip: Mix heavy sizes (like 370mm ties) with light sizes (100mm) to maximize volume without exceeding weight limits.

Q: Can I get samples before ordering?

A: Yes. We always recommend testing a random sample kit. Do not just look at them—install them, pull them, and put them in the freezer overnight to test cold resistance.

Summary

Nylon cable ties are precision-molded fasteners, not just pieces of plastic. By understanding the importance of Virgin PA66, proper moisture content, and tensile strength ratings, you can protect your business from costly quality claims.

Whether you need a specific UL rating or a custom retail package for your brand, we are here to help you configure the right product for your market.

Ready to upgrade your inventory?

Contact our export team today to request your free sample kit or download our full specification sheet.