When you ship or sell cable ties worldwide, one of the most common questions from your customers is simple: “How long will these ties last outside?”

The answer depends on what they’re made of, where they’re used, and how they’re handled — but there’s real data you can use to make smart buying decisions.

Why Lifespan Matters for Your Business

A zip tie that fails too soon doesn’t just break — it breaks trust.

- Importers: Under-spec’d materials can lead to returns, product claims and wasted freight costs.

- Distributors: Selling the right tie for each environment reduces customer complaints and strengthens your reputation.

- OEM brands: Outdoor durability is part of your brand promise — a failed tie can mean a failed product.

Outdoor lifespan also affects replacement cycles and inventory turnover. A tie that lasts 7 years instead of 2 means lower maintenance and higher long-term savings for your clients.

Key Factors That Affect Outdoor Lifespan

Material & Additives

Most zip ties are made from nylon 6/6, a strong, lightweight polymer. However, standard nylon degrades quickly under UV exposure.

Adding a UV stabilizer or switching to nylon 612 can extend lifespan from 1–2 years to 7–9 years outdoors. Learn more on Nylon 6/6 here →

UV & Sunlight Exposure

Sunlight is the #1 cause of polymer aging. Constant UV exposure breaks molecular bonds, causing color fade and brittleness.

Black UV-resistant ties last significantly longer than natural (clear) ties because the carbon black pigment blocks UV light.

Temperature, Moisture & Chemicals

Extreme heat accelerates oxidation; cold makes plastic brittle. Humidity and salt air can shorten lifespan by 20–40 %.

Chemicals like fuel, oil and solvents also attack nylon chains over time.

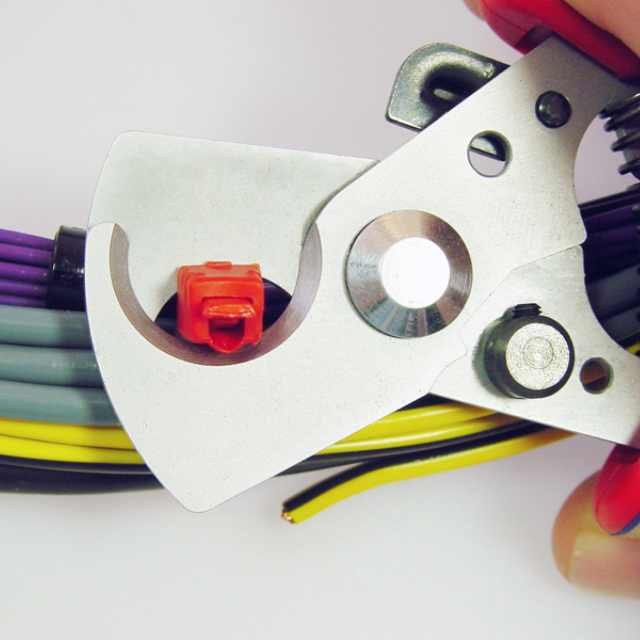

Mechanical Stress & Load

Over-tightening, vibration or constant pull stress cause micro-cracks that lead to failure. Correct tensioning tools can increase life by up to 30 %.

Typical Lifespan Ranges by Material

| Material Type | Typical Outdoor Life | Key Features |

|---|---|---|

| Standard Nylon 6/6 | 6 months – 2 years | Low cost; indoor use recommended |

| UV-Stabilized Nylon 612 | 7 – 9 years | Resists UV and humidity; ideal for solar & telecom projects |

| Stainless Steel / Coated Metal | 5 – 10 + years | High heat & chemical resistance; marine & industrial use |

What Importers, Distributors & OEMs Should Look For

Specification Checklist

- Material: Nylon 6/6 or 612, 316 stainless steel, or coated metal.

- Tensile Strength: 18 lbs – 250 lbs depending on application.

- Temperature Range: –40 °C to +85 °C (standard) / up to +150 °C for metal ties.

- UV Rating: Black ties with carbon black content ≥ 2 %.

- Certifications: UL, ISO 9001, RoHS compliant.

Certification & Quality Control

Always verify manufacturer testing reports and batch certificates. Look for consistent tensile tests and aging data.

If you supply OEM clients, request a UV aging test report (ASTM D638) for documentation.

Supplier Questions & Sample Testing

Before placing large orders, ask your supplier:

- What UV stabilizer formula is used?

- How are ties stored before shipment?

- Can you provide sample ties for accelerated UV testing (1,000 hours)?

At HCableTie, we offer sample packs for outdoor field testing — ideal for OEM approval processes.

Request a sample now →

Tips to Maximise Outdoor Lifespan

- Proper Installation: Use a tension tool to avoid over-tightening and cutting the strap.

- Inspection Schedule: In hot or UV-intense regions, inspect every 2–3 years. Replace if ties show discoloration or cracking.

- Storage Before Use: Keep in sealed bags under 25 °C. Avoid sunlight and moisture exposure in warehouses.

- Choose Color Wisely: Black ties outlast white by 2× to 3× under UV radiation.

Real-World Case Study

Example 1: Solar Farm in Arizona

A solar installation used UV-stabilised nylon 612 ties for panel cable management.

After 5 years under intense sun and 50 °C heat, inspection found 90 % ties still functional — compared to 1-year failure on standard nylon.

Example 2: Coastal Telecom Project in Malaysia

316 stainless-steel ties were installed near the shoreline. Despite constant humidity and salt spray, they remained corrosion-free for 8 years.

This saved the client an estimated USD 12,000 in annual maintenance.

Summary

Outdoor zip tie lifespan depends on three main factors: material type, environmental exposure, and installation quality.

Standard nylon may last under 2 years, but UV-stabilised nylon 612 and metal ties can serve for a decade or more.

If you supply or manufacture for outdoor applications — solar, electrical, telecom — it pays to choose the right grade from the start.

📩 Ready to upgrade your outdoor range?

Contact our export team → for a free consultation and spec sheet download.